Allowed materials

High melting point materials such as ceramics, semiconductors, and refractory metals. Other metals are looked at case by case depending on the annealing temperature and the respective gas partial pressure. No polymers and no liquids.

Things that are good to know before requesting the training

The maximum operating temperature is 1 200 °C, and the lowest practical temperature is 300 °C.

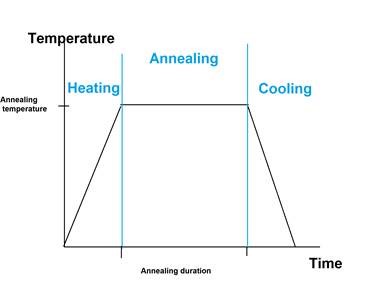

The furnace doesn't start the annealing at a certain temperature immediately. The heating takes time and depends on the temperature you are going to use. The lower the temperature, the slower the ramp rate is. The reasonable ramp rate is 3 degC/min for 300C. Such low ramp rate helps to prevent overheating for sensitive samples. Thus, only ramping to 300C takes 1h 40 mins.

Secondly, there is no cooling system and the chamber cools down naturally. The cooling time depends on the temperature you are using. The higher the temperature, the longer it takes to cool the chamber down. You can leave the furnace for cooling overnight and there is no charge for that.

Thus, there are three parts in every annealing run and the actual time when the sample is in the chamber is much longer than the actual annealing. Please, take these features of the furnace into account and consider if the furnace is suitable for your samples.

Please, include in your application the following information

1. Thin films you are going to anneal and the substrate material

2. Melting points for all materials in the sample at vacuum level. Please remember that melting point is usually lower at vacuum.

3. Annealing time and annealing temperature you are going to use

4. Were any polymers (e.g. photoresists) involved in the sample fabrication? General cleanliness of the sample.

The furnace is also equipped with a residual gas analysis system, which is used to measure the residual gas atoms and molecules in the vacuum manifold.

The oven can be operated under high vacuum at < 0.05 mPa, depending on how much off gassing there is. Nitrogen atmosphere can also be used during annealing. In this case the maximum operating temperature is lower, up to 400 °C. Higher temperatures can be considered if the annealing time is short.